Automatic 16 Channel Vibration Intelligent Visual Capsule Counting Machine PBDS-16

Automatic 16 Channel Vibration Intelligent Visual Capsule Counting Machine PBDS-16

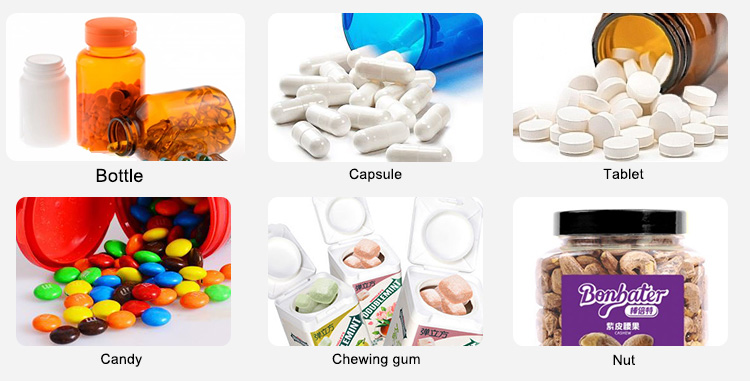

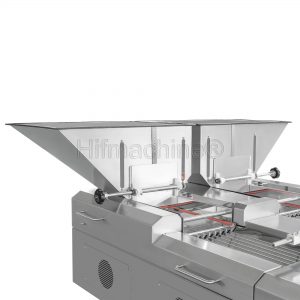

The PBDS-16 is an efficient and accurate drug counting equipment that can be widely used in medicine, health care products and other industries. The equipment uses advanced visual sensing technology to automatically identify and count tablets of various shapes, greatly improving production efficiency and counting accuracy. At the same time, the equipment is simple to operate and easy to maintain, making it one of the indispensable and important equipment for modern production lines. This equipment has the characteristics of high resolution, double-chip recognition, particle removal, particle dust prevention, full-process recording, simple operation, stable scanning cycle, powerful human-machine interface and convenient system maintenance, and can meet various production requirements. , and help improve production efficiency and reduce production costs.

Feature

2) Double-chip recognition: It can accurately identify the lamination situation and determine the number of laminations by calculating the projected area. The accuracy is more than 10 times higher than that of infrared sensors.

3) Rejection of broken particles: By measuring the width and falling time of the medicine particles, small particles and normal medicine particles can be accurately distinguished, and about one-third of the fragments can be removed.

4) Anti-particulate dust: The CCD camera with backlight imaging and the automatic dimming light source can automatically increase the brightness of the light source as the dust increases, and the CCD camera is far away from the dust generation place and is not easy to be polluted.

5) Full-process recording: Equipped with a 32G memory card internally, it can record the projection data and production time of the medicine particles produced in the past year to facilitate product traceability and equipment debugging.

6) Simple installation, debugging and use: Easy to operate, equipped with video tutorials for easy installation, debugging and replacement.

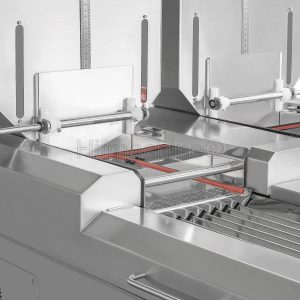

7) Stable scanning cycle: Using an advanced quad-core processor, there is a scanning cycle for every 1mm movement, with high stability.

8) Powerful human-machine interface: It has functions such as device control, video playback, real-time image display and historical image viewing, and supports subsequent development.

9) System maintenance is convenient: the equipment can be connected to the Internet for remote upgrade of human-machine interface software, CCD sensor system and measurement and control mainboard system.

10) Automatic alarm for lack of material in the silo and automatic shutdown function when there is no material.

11) The double-axis cylinder controls bottle feeding, filling and placing, with simple structure, convenient adjustment and stable control.

12) The photoelectric control device automatically stops the machine when there is no bottle or the bottle is blocked, and automatically starts operation after returning to normal.

13) The electric adjustment method adapts to bottles of different heights and is controlled through the touch screen.

14) When the equipment fails, it will stop and display an alarm message, and provide operation methods on the screen for troubleshooting.

15) The modular design structure and cylinder locking component enable tool-less disassembly, making maintenance and repair easier.

16) The vibration module combined with full-wave frequency conversion and spring reduces noise level.

Summary of functions

1. Automatic fill light function (to ensure that the camera has enough light to distinguish)

2. Electric lifting function (facilitates adjustment of bottle height)

3. Tool-less disassembly design (modular design, easy to maintain and maintain, while avoiding the risk of potential foreign matter falling into the blanking nozzle)

4. The function of removing excessive grains, missing grains and broken grains (identification by camera imaging)

5. Configuration of the drug recovery tank (to prevent bottles from being accidentally dumped on the conveyor belt and causing materials to scatter on the ground)

6. Automatic shutdown function for blocked bottles, insufficient bottle supply, and bottle inversion (through infrared photoelectric detection)

7. Intelligent functions such as permission setting, data collection, variety storage, working status, maintenance reminders, fault handling methods, data terminal reservation (optional data tracking, instant printing, SCADA system docking)

8. Comprehensive dust removal function with upper and lower suction (to ensure the best dust removal effect)

9. Anti-stacking/capsule, anti-static and anti-interference functions (to ensure the accuracy of counting pills)

| Model | PBDS-16 |

|---|---|

| Number of vibration orbits | 16 |

| Maximum production speed | 8000 capsules/min (depending on the size of the medicine) |

| Quantity | 1~9999 capsules |

| Drug Specifications | Thickness: 3~10mm Diameter: 3~20mm Length: 3~30mm |

| Bottle Diameter | 20~200mm |

| Bottle Height | 40~240mm |

| Power Supply | AC 220V 50/60Hz |

| Power | 1.2kW |

| Air Pressure | 0.6MPa |

| Air consumption | About 200L/min clean air |

| Dimensions | 2600×1640×1530mm |

| Silo Volume | 70 L |

| Weight | About 700kg |

Comprehensive Solutions

Explore HiF Machine’s extensive lineup of pharmaceutical machinery and packaging solutions, tailored for maximum efficiency and value.