Multi-Channel Tablet And Capsule Counting Machine CED-8

Multi-Channel Tablet And Capsule Counting Machine CED-8

The product uses the principle of photoelectric induction to count, separate and transport the sensed medical particles, and can monitor and set all operating data in real time. The product is an 8-channel counting machine, that is to say, there are 8 vibrating “V” grooves on the vibrating plate of the worktable, which can work at the same time, and the particles that are automatically transferred into the lower hopper by the vibration effect are counted one by one. A bottle blocking electromagnet is installed on the side of the rail to ensure that the bottle will not move during bottling. When the set quantity is filled, the electromagnet will automatically open and the bottle will be transported by the rail. On the left side of the track is equipped with a bottle-watching photoelectric eye to detect whether there is an empty bottle waiting for the next bottling work. If there is no bottle, repeat the above operation. If there is no vibration device, it will stop working and realize automatic counting. The body is made of high-quality stainless steel, with exquisite dimensions, simple structure, beautiful appearance and easy maintenance.

Remarks

- During the operation of the equipment, the operator should pay close attention to the operation of the equipment, make a good record of the operation of the equipment, and record the operation of the equipment in detail, so as to provide reference for the equipment maintenance personnel in the inspection and maintenance of the equipment. If any abnormality is found, the machine must be shut down immediately and the maintenance personnel shall be informed to deal with it. The machine can be restarted after troubleshooting.

- Equipment maintenance personnel should carry out regular inspection, maintenance and maintenance of the equipment.

- Before maintaining the equipment, first disconnect the power supply, and comply with the relevant safety norms. Any fixed protective device needs to be opened or removed for maintenance. After maintenance, it must be returned to its original position intact.

- Clean the dust once a week, and dedust the electrical components of the electrical control cabinet.

- It is best to continue to work every other week. All terminals of the machine should be stable and prevent poor contact.

- Be careful to check whether the motor wire has peeling or other phenomena. If so, please replace the wire immediately to prevent short circuit and electric shock accidents.

| Model | CED-8 |

|---|---|

| Rate of production | 10~30 bottles/min |

| Single bottling capacity | 2-9999pcs/bottle |

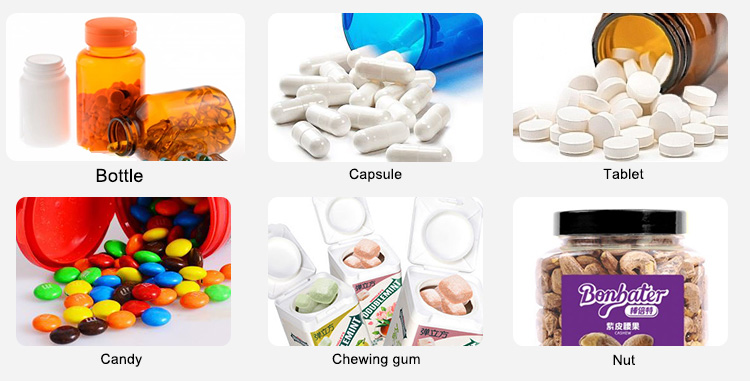

| Common type | pells, tables, soft and hard capsules and oter solid tablets |

| Phar,aceutical specifications | φ3~φ20mm solid granules, 0~5# hard capsules, soft capsules, other solid granules |

| Bottle diameter | φ20~φ100mm |

| Bottle height | 40-240mm |

| Power supply | AC 220V 50/60Hz |

| Air pressure am consumption | 0.6~0.8MPa, 3.5L/min |

| Power | 0.8kW |

| Overall dimension(L*W*H) | 1350mm*1400mm*1650mm(Level 2)

1650mm*1400mm*1650mm(Level 3) |

| Machine weight | About 250kg/300kg |

Comprehensive Solutions

Explore HiF Machine’s extensive lineup of pharmaceutical machinery and packaging solutions, tailored for maximum efficiency and value.