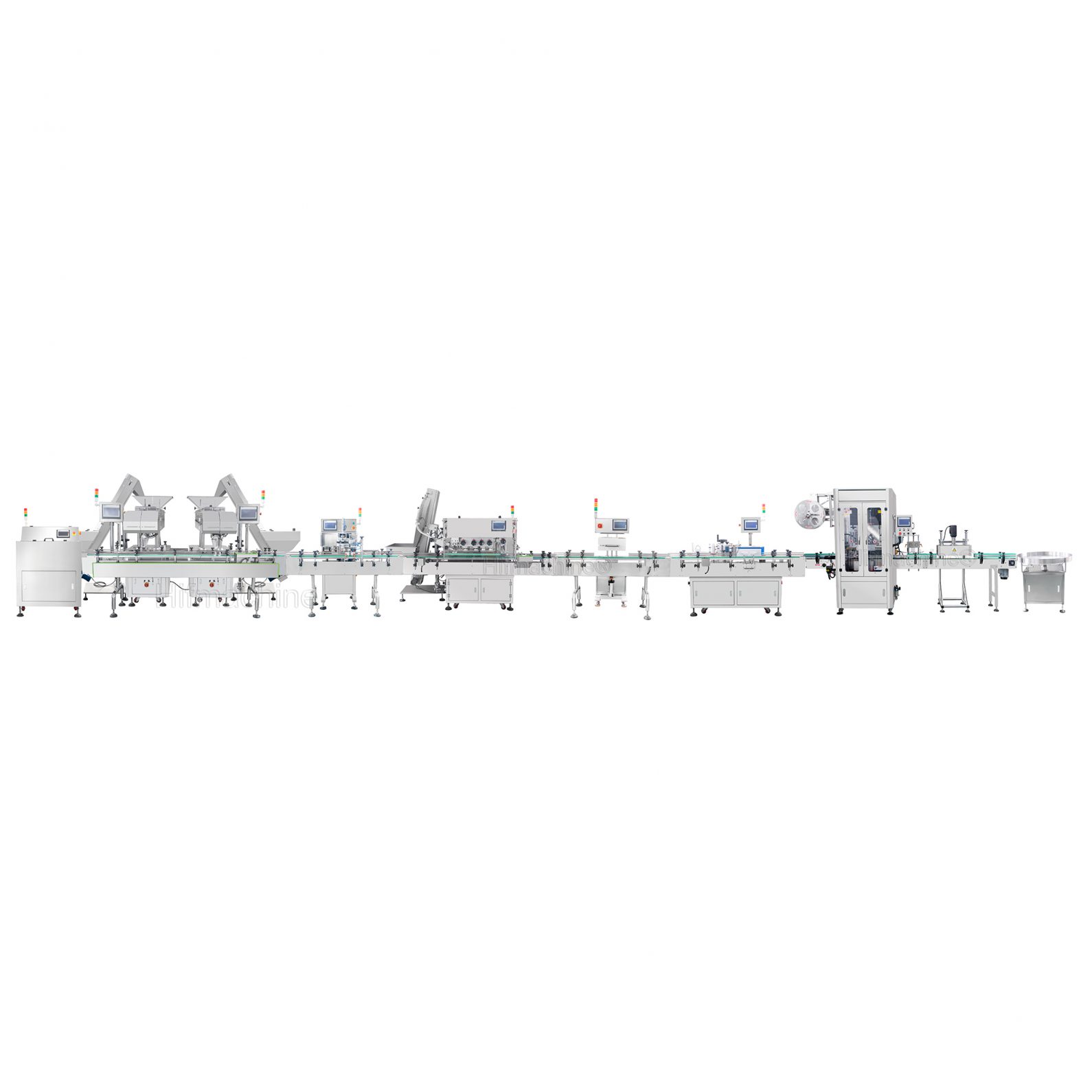

Tablet Capsule Counting Sealing Labeling Line

Tablet Capsule Counting Sealing Labeling Line

Counters, bottle fillers and other assembly lines designed in accordance with cGMP requirements have been widely used and highly respected around the world. We have developed a complete set of exquisitely designed and well-made machines, from unscrambling to final packaging. The complete sets of equipment produced by our company include: bottle unscrambler, feeding machine, tablet/capsule counting machine, cotton yarn inserting machine, capping machine, labeling machine, induction sealing machine. We provide our customers with the best comprehensive solutions to meet their various needs.

Bottle UnscramblerBottle-Supplying Machine Lifting Feeder

- It is widely used for automatically arranging and directionally conveying bottles in various shapes and specifications in pharmaceutical industry. It is an ideal matching equipment for various plastic bottle production lines and is widely used in chemical industry, light industry, food and beverage industries.

| Model | BotCN-Uns 9 |

| Max. output | 150 bottles/min |

| Bottle size | 15-300 mL |

| Voltage | 220V /50 Hz |

| Power | 0.5kW |

| Air pressure | 0.3~0.6 MPa |

| Dimension( L×W×H) | 1100×1740×1200 mm |

| Weight | 337kg |

Lifting Feeder

- The machine is composed of hopper, lifting conveyor, frequency converter and so on. It is conveyed by closed soft silica gel, which meets the hygienic requirements. The bottom is equipped with movable rollers for easy adjustment and displacement.

|

Electrical Counting Machine

- Electronical counting machine is mainly used in pharmaceutical, food and chemical industry hardware etc. The utility model relates to an automatic device for accurate counting and filling of tablets, pills, capsules and special-shaped tablets. Through automatic counting and filling of products, the efficiency of labor production is greatly improved, and the artificial pollution caused by manual counting and filling in the past is avoided. Electrical counting machine is more accurate than mechanical rotary counting machine and is more suitable for high accuracy requirement.

| Model | BotCN-Cou 270 | |||

| Num.of channel | 8 | 12 | 16 | 24 |

| Max. capacity(count/min) | 4000 | 6000 | 8000 | 12000 |

| Fill qty | 1~1000 | |||

| Product size(mm) | Thinkness:3~10mm; Diameter:3~13mm ; Length:3~21mm | |||

| Container size(mm) | Dia.:20~100mm Height:40~240mm | |||

| Power | AC 220V 50/60Hz | |||

| Power consumption | 1.0kW | 1.2kW | 1.5kW | 1.8kW |

| Compressed air supply (MPa) | 0.6MPa | |||

| Compressed air consumption (L/min) | Approximately 100L/minClean air | 130 | 200 | 260 |

| Measurement (L×W ×H)(mm) | 1325×1610

×1770 |

1325×1610

×1770 |

1580×1680

×1770 |

1666×1610

×1770 |

| Hopper capacity (L) | 28 | 34 | 50 | 60 |

| Weight (kg) | 600 | 600 | 700 | 800 |

Cotton Inserter

- Automatic Cotton Inserter can be widely used in pharmaceutical, health products and food industries, and the strip cotton can be automatically loaded into containers. This machine can be matched with other machines to form a bottling line.

| Model | BotCN-Lns 4.2 |

| Bottling speed | 10-60 bottles / min |

| Cotton length | 5-180mm |

| Overall dimension | 850 mm × 650 mm × 1350 mm |

| Conveyor belt length | 1800 mm |

| Bottle dia | Ф 20~ Ф 100 mm |

| Bottle height | 30-250 mm |

| Net weight | 100 kg |

| Noise | ≤ 75dB (a) |

| Compressed air | 0.5MPa |

| Power supply | AC 220 V, 50 Hz |

| Power | 400W |

High-Speed Capping Machine

- The machine is suitable for the bottle in the shape of round, square, oval, or flat side, and it is the ideal equipment for automatic cap-screwing process in pharmaceutical, food, chemical and other industries. This machine can be used separately and it also can match sealing, labeling and other ancillary equipment to form a wonderful production line.

|

Induction Sealing Machine Labeling Mchine

- This automatic induction sealer is required as a single unit over a conveyor for hassle-free mounting and sealing applications with adjustable height and is providing with mobile trolley for easy movement.

| Model | BotCN-Sel 24 |

| Bottle neck diameter | 20mm-60mm / 50-120mm(customizable) |

| Bottle height | 0mm-450mm |

| Flow packing line speed | 0-35 m/min |

| Sealing speed | 0-400 bottles/min |

| Max power | 4000W |

| Electricity power | 220V,50/60Hz |

| Induction sensor size | 450mm*200mm*90mm |

| Machine size(L*W*H) | 510mm*750mm*1380mm |

| Machine net weight | 85kg |

| Packaged size | 600mm*560mm*700mm 930mm*830mm*280mm |

| Package weight | 120kg |

Labeling Mchine

- The machine is widely used for round bottles of different sizes and plastic bottles of different specifications in pharmaceutical sector. It is an ideal supporting equipment for various plastic bottle production lines. It can also be used in plastic bottle production lines in chemical industry, light industry, food and beverage industries.

| Model | BotCN-Lbl 10.8 |

| Max output | 180 bottles / min |

| Length of labels | 20~250mm |

| Width of labels | 20~75mm |

| Suitable bottle range | 15~300mL |

| Height of bottles | 30~150mm |

| Voltage/Frequency | AC 220V/50Hz |

| Power consumption | 2kW |

| Dimensions(LxWxH) | 1950x1060x1300mm |

| Weight | 237kg |

Automatic Bottle Unscrambler

- Automatic Bottle Unscrambler is suitable for pharmaceutical, cosmetic, food and other industries. It can convey glass bottles, plastic bottles, round bottles and square bottles. The product can convey bottles to the next working procedure, making it more efficiently to arrange bottles.

|

Comprehensive Solutions

Explore HiF Machine’s extensive lineup of pharmaceutical machinery and packaging solutions, tailored for maximum efficiency and value.