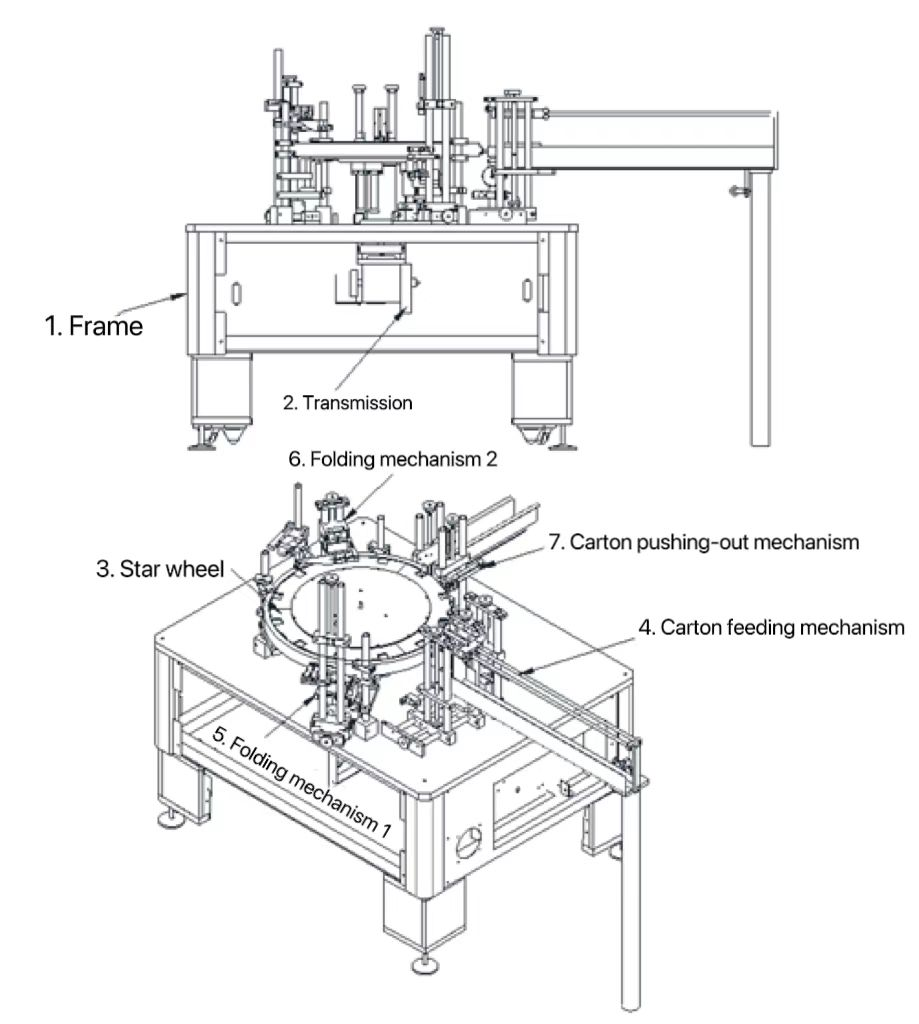

Turntable Cartoning Machine DZH-50S

Turntable Cartoning Machine DZH-50S

This machine uses vacuum suction cups to feed cartons into the star wheel. The empty cartons are rotated by the star wheel to the folding mechanism 1 to seal the bottom of the carton. After the finished product to be packed is manually placed into the carton, the star wheel rotates the carton to the folding mechanism 2 to seal the top of the carton. Finally, the completed product is transferred by the star wheel to the carton pushing-out mechanism for delivery.

The machine consists of the following main parts:

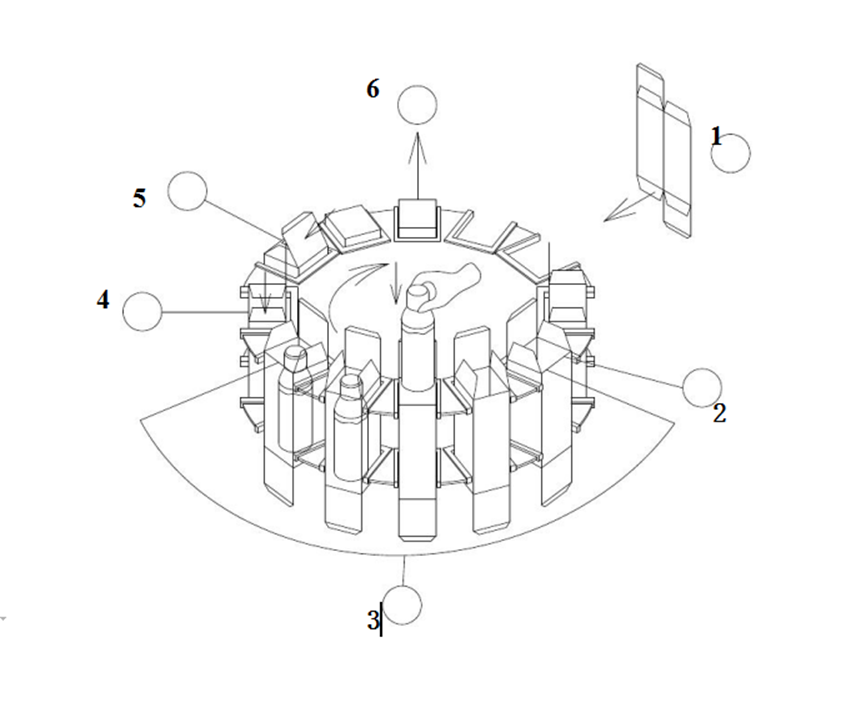

Workflow Steps

-

The vacuum suction cup device on the carton feeding mechanism holds the carton and feeds it into the star wheel fixture, then a set of cylinders from below fold the inner small flaps.

-

After the carton is transferred to this station, the stopper cylinder on the ear folding mechanism 1 blocks the large ear, and the ear folding cylinder folds the large ear into the carton, followed by the flattening of the large ear by the ear pressing cylinder.

-

Place the desired items into the carton.

-

The rotating cylinder on the ear folding mechanism 2, together with the ear pressing rod, folds the inner small flaps on the top of the carton.

-

After the carton is transferred to this station, the stopper cylinder on the ear folding mechanism 2 blocks the large ear, and the ear folding cylinder folds the large ear into the carton, followed by the flattening of the large ear by the ear pressing cylinder.

-

After the finished product of carton folding is transferred to this station, a set of pushing cylinder pushes the finished product out of the star wheel.

Maintenance and Care for Machine

- Keep the machine clean by wiping it regularly and occasionally tightening screws near the cylinder to prevent loosening.

- In case of malfunction, analyze carefully and have relevant mechanics repair and troubleshoot. Do not adjust or dismantle components at will to avoid damaging the machine.

| Model | DZH-50S |

|---|---|

| Carton minimum dimensions | 60*20*20mm |

| Carton Maximum dimensions | 200*80*80mm |

| Production speed | 20-60 cartons/min |

| Power supply | 220V single phase;50/60Hz |

| Horsepower of motor | 1/4HP 15:1 |

| Air pressure consumption | 150L/min |

| Machine dimensions(mm) | 1750L*1200W*1500H |

| Machine Weight | 950kg |

Comprehensive Solutions

Explore HiF Machine’s extensive lineup of pharmaceutical machinery and packaging solutions, tailored for maximum efficiency and value.