Fully Automatic Auger Filler Line

Fully Automatic Auger Filler Line

The line of semi-automatic auger fillers is the ultimate in operator convenience. The innovative design and PLC-based controls make each filler an affordable, reliable auger filler with the same rugged construction.

It is the ultimate in operator convenience – precision engineered for time saving, cost cutting performance.

Remarks

- Reduce dust, reduce labor intensity – improve labor efficiency; the material mouth is a round material mouth, and there is no dead angle for cutting.

- Wide range of applications – This product is mainly used for powder and pellet loading, and is suitable for equipment loading in industries such as food, chemical, building materials, plastics and packaging.

- Wide range of applicable materials – capable of handling a variety of powder materials, storage tanks and spiral conveyor tubes are made of stainless steel;

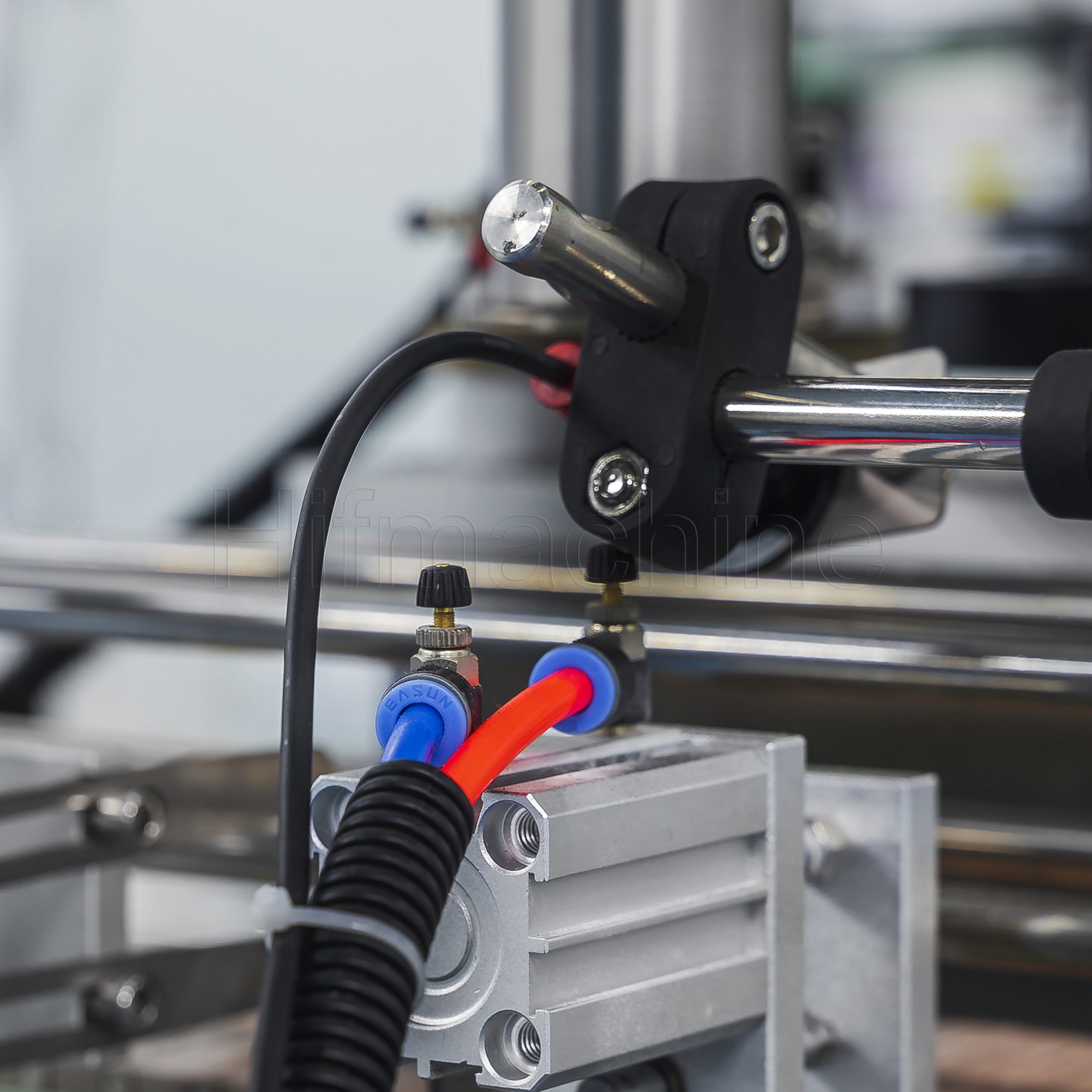

- The vibration amplitude is adjustable – the vibration amplitude of each switch of the feeding motor and the vibration motor is adjustable, and the whole spiral can be easily disassembled and cleaned.

- Easy to disassemble – soft connection between storage bin and screw conveyor, easy to disassemble;

- Convenient cleaning – the lower end of the storage bin has a discharge port and a positive and negative switch for easy cleaning;

- Convenient feeding – the storage tank is equipped with a vibration motor, so that the material passes through the spiral conveying pipe to the discharge port.

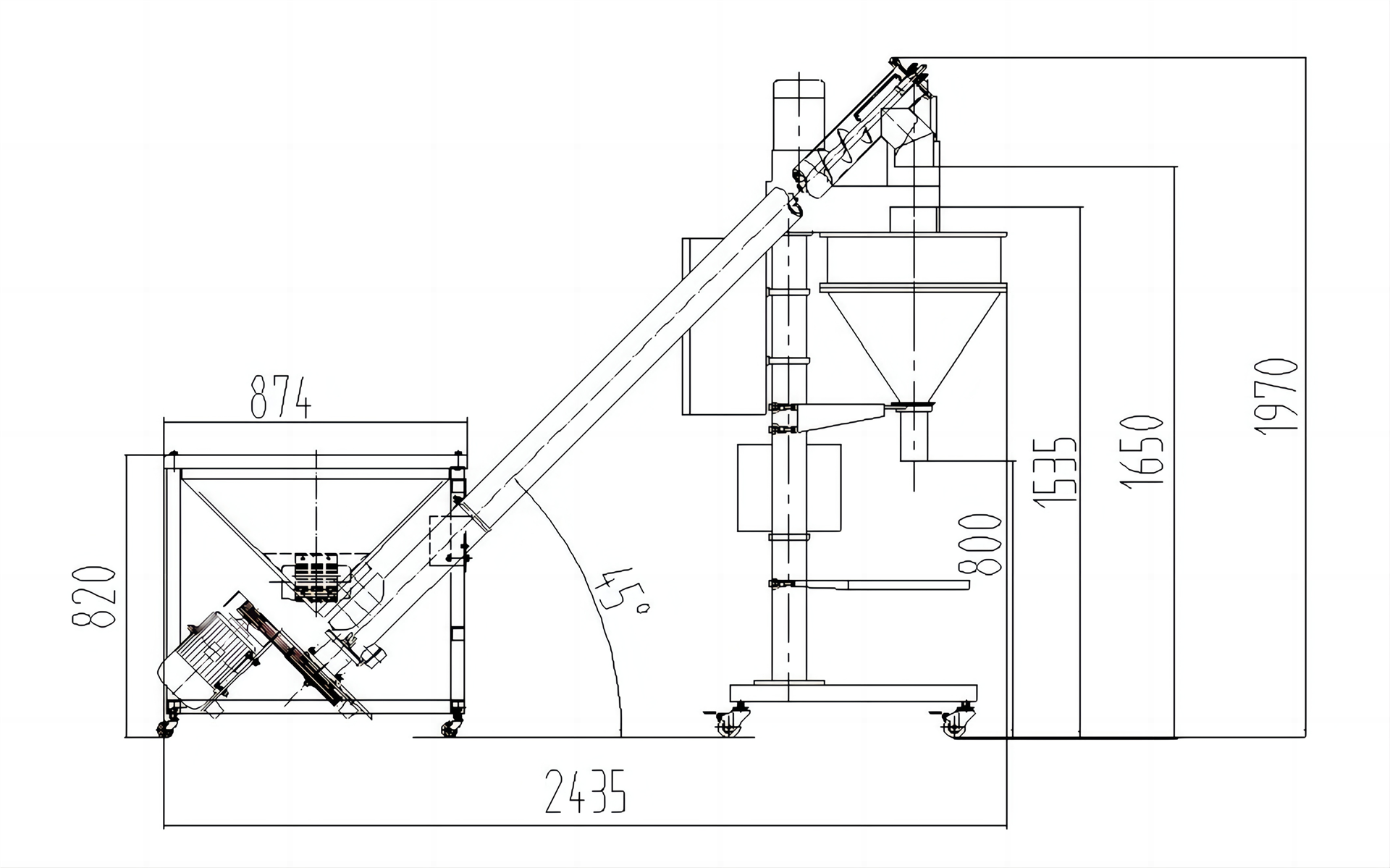

Structure

| Model | HZSL-B |

|---|---|

| Feeding height | 1600mm |

| Volume | 120L |

| Voltage | AC220V, 50/60Hz |

| Power | 1.8kW |

| Dimensions | 2200mm*900mm*2050mm |

| Machine package dimensions | 1140mm*1030mm*1180mm |

| Feeder package dimensions | 2450mm*240mm*500mm |

| Machine package weight | 147kg |

| Feeder package weight | 40kg |

| Model | CN-HZFC |

|---|---|

| Filling container | wild-mouth bottle |

| Filling specifications | 10g-5000g (Replace the screw part) |

| Filling accuracy | 1% |

| Input voltage power | AC220V 50Hz 1000W (Without feeding machine) |

| Filling speed | 10-40 bottles/min (depending on the material quality, filling specification, professionism of operators) |

| Suitable bottles | diameter of bottle body 20-150mm; bottle height 60-300mm |

| Total Wt | 360kg |

| Overall dimension (L*W*H) | 2000*980*2000mm |

Comprehensive Solutions

Explore HiF Machine’s extensive lineup of pharmaceutical machinery and packaging solutions, tailored for maximum efficiency and value.