Automatic Single-Row Powder Back-Sealing Packaging Machine CBZ-50F

Automatic Single-Row Powder Back-Sealing Packaging Machine CBZ-50F

CBZ-50F automatic single-row powder back-seal packaging machine combines efficient filling, sealing and cutting technologies to ensure the stability and reliability of the packaging process. The equipment is driven by a stepper motor, and the bag length can be freely set within a specified range to ensure the stability and reliability of the bag pull, and the speed is adjustable. In addition, the equipment also has an automatic photoelectric detection function, which can realize automatic detection, positioning, sealing and cutting of pattern integrity to ensure the beauty and integrity of the packaging bag. When the packaging material is insufficient, the equipment will automatically stop to prevent running without material. The equipment is also equipped with self-diagnosis and fault indication functions, which is convenient for users to find and solve problems in time.

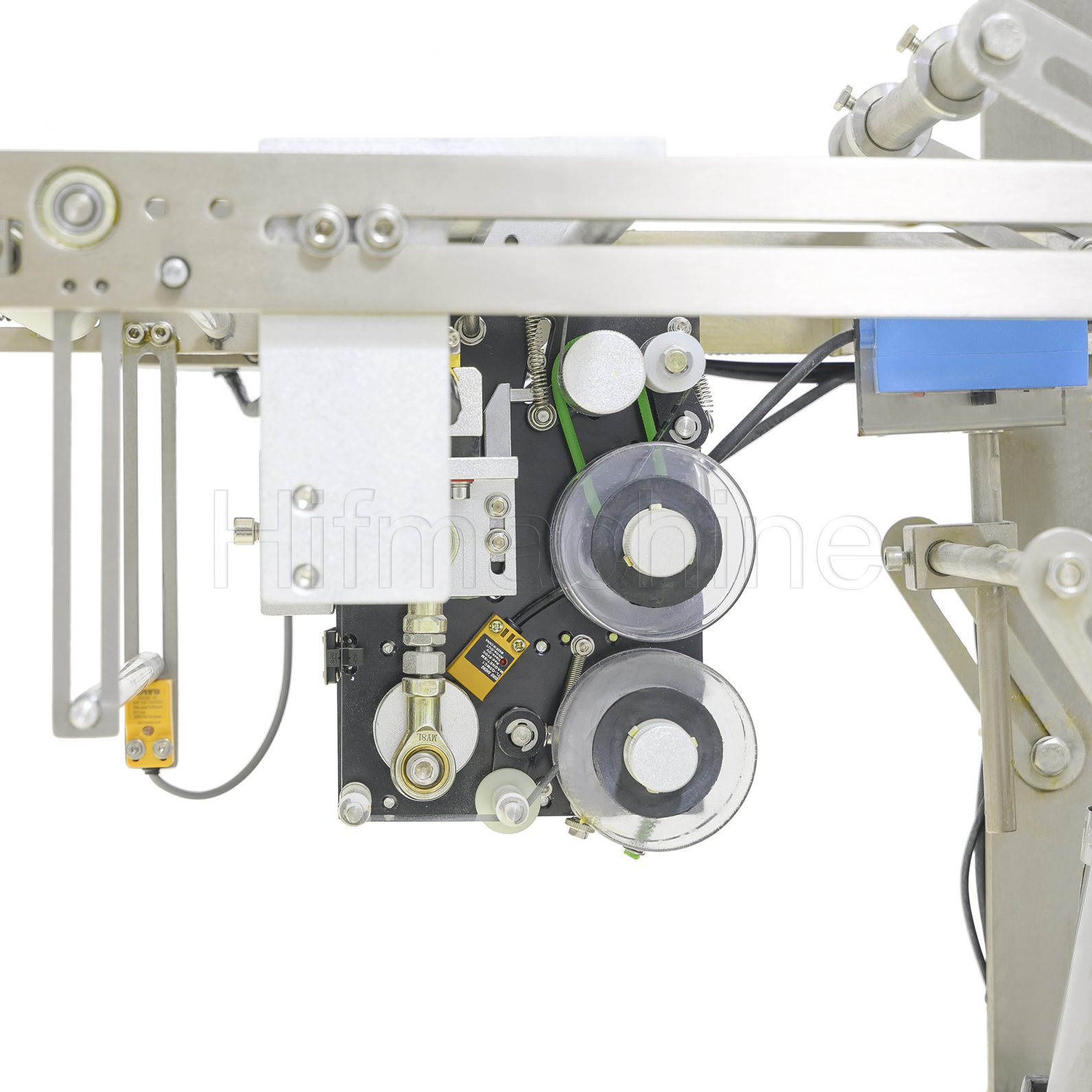

- Efficient production: Automatically complete the processes of bag making, metering, filling, sealing, printing production date, tearing, cutting and counting.

- Precise control: Driven by a stepper motor, the bag length can be freely set and the speed is adjustable to ensure the stability and reliability of the bag pulling.

- Automatic detection: Equipped with automatic photoelectric detection function to ensure the integrity and aesthetics of the packaging bag pattern.

- Automatic shutdown: Automatic shutdown when the packaging material is insufficient to prevent running without material.

- Self-diagnosis: Built-in self-diagnosis and fault indication functions are convenient for users to find and solve problems in time.

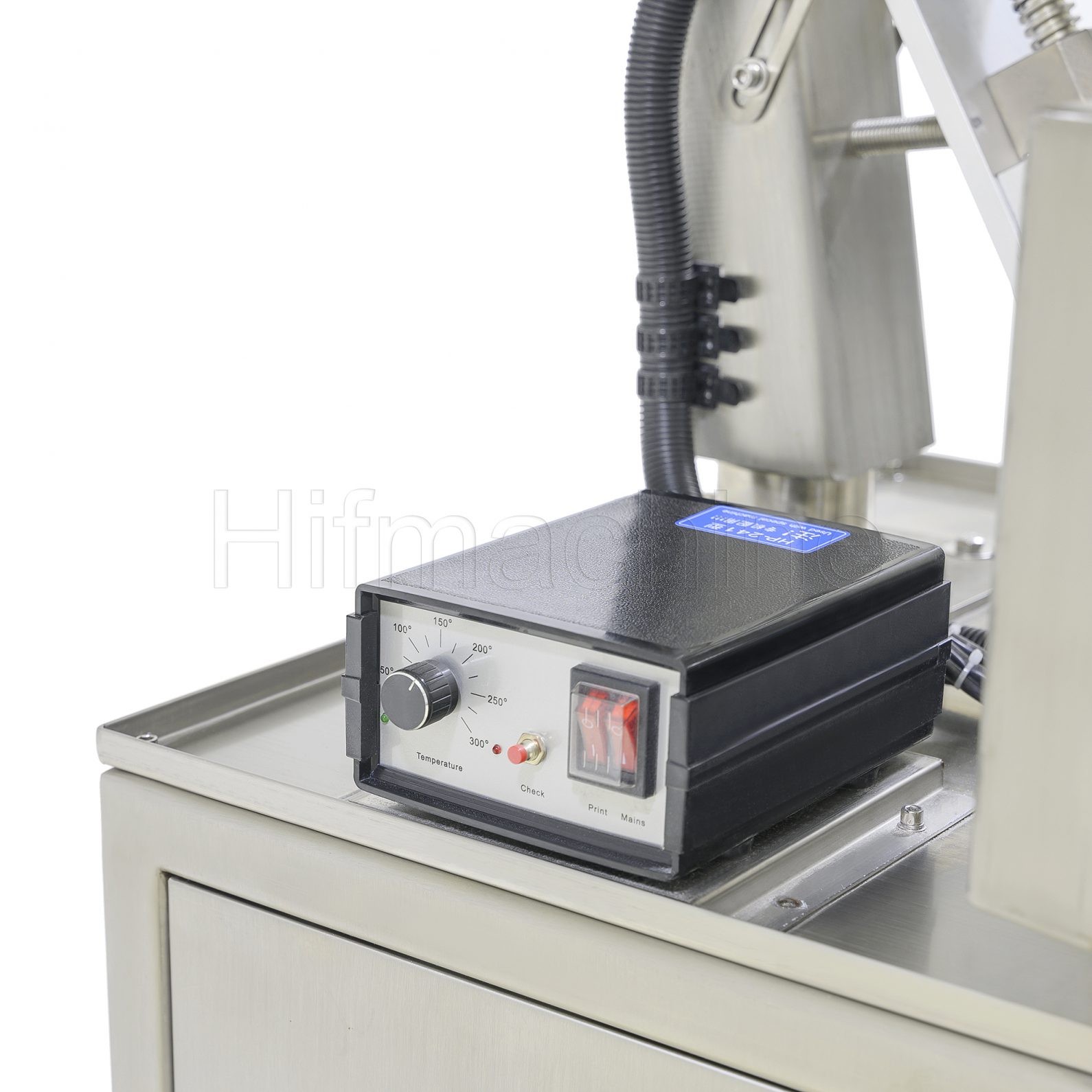

- Temperature control: Adopts high-precision PID temperature control system to ensure the heat sealing quality of different materials.

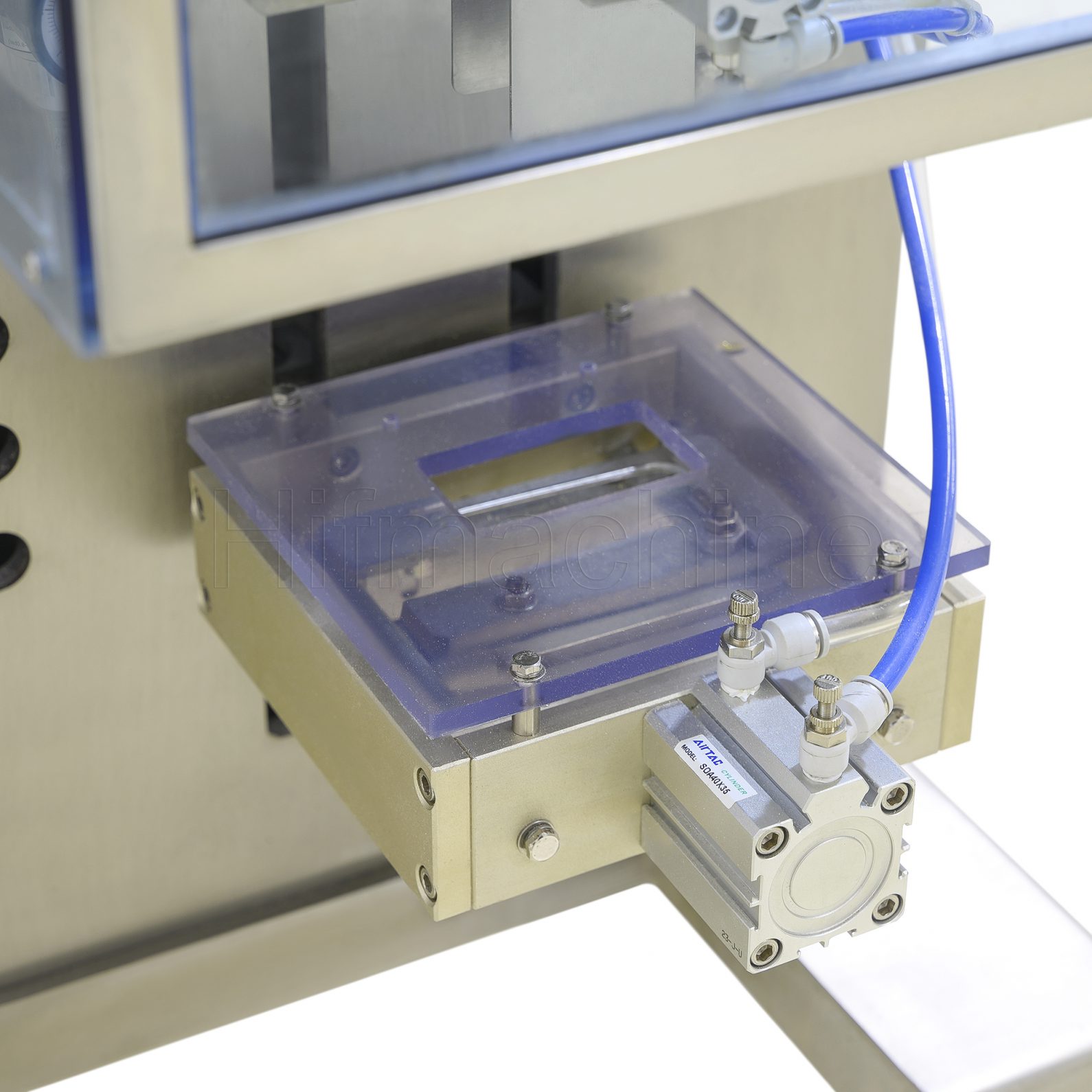

- Easy operation: The intermittent structure is simple and easy to operate and maintain.

- Versatility: By replacing different filling heads, multi-purpose packaging can be achieved.

- Additional functions: Optional batch number printing and tearing functions are available to improve the convenience of use.

- High-quality components: Adopt high-quality components to ensure stable equipment performance, low noise, low failure rate and long service life.

| Model | CBZ-50F |

|---|---|

| Packaging speed | Up to 60 bags/min |

| Bag length range | 50-200 mm |

| Bag width range | 50-150 mm |

| Packaging materials | PE, PP, PET, aluminum foil composite film, etc. |

| Power supply | AC220V/50Hz or AC110V/60Hz |

| Power | 1.5 kW |

| Compressed air | 0.6 MPa, air consumption 0.3 m³/min |

| Dimensions (Length, Width, Height) | 1200 * 700 * 1800 mm |

| Weight | 350 kg |

| Application range | Powder products, such as food, chemicals, medicine, etc. |

Comprehensive Solutions

Explore HiF Machine’s extensive lineup of pharmaceutical machinery and packaging solutions, tailored for maximum efficiency and value.