High Filling Accuracy Automatic Capsule Filling Machine NJP-1200D

High Filling Accuracy Automatic Capsule Filling Machine NJP-1200D

NJP-1200D automatic capsule filler processes the products for optimal productivity up to 1200 capsules per minutes, featuring low-maintenance operation, minimal downtime, and overall dependable production.

Powder dosing uses the 5 stage tamping technology for an enhanced accuracy. Filling of pellets is available.

Capsules from the bunker are fed into the orienting device along the vertical guide.

Then they are transferred into special cells on the rotor. Here the capsule is separated, after what the bottom part comes to the filling position.

After filling the bottom part with the material, on next positions the non-separated capsules are rejected, and the filled bottom parts are joined with top parts, counted and taken away into the receiving box.

The equipment design is fully in line with the requirements of CGMP and FDA specification.

Working Principle

NJP-1200D can be used to encapsulate powder, granules and pellets in pre- determined dosages.

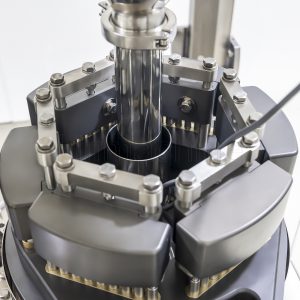

The filling of the capsules is carried out in the upper segment of the machine consisting of components like capsule hopper, powder hopper, 10 stations on a rotary plate, filling station assembly and other components as part of filling process. Upper and lower segments of the automatic capsule filling machine can be labeled as below.

Remarks

- Powder filling system is very high filling accuracy.

- The capsule-type rejection system effectively protects the filled capsules from breaking by the machine.

- The patented modular punch as well as the bi-nodal feed hopper is of simple dismounting and with accurate positioning.

- All the connectors of the air pipes apply standardized clamps, which are much easier to dismantle and clean than others.

- The whole set of the molds and all the parts that need daily cleaning and maintenance are equipped with locating pins, and the connection as well as fastening among different parts is extremely simple. As the fastening tool is standardized in size, a small spanner can easily dismount all the parts.

| D Type Automatic Capsule Filling Machine | ||

|---|---|---|

| Machine model | NJP-1200D | NJP-3000D |

| Max capacity | 72000capsules /h | 165000capsules /h |

| Suit for capsule size | 000#-5# and safety capsule | 000#-5# and safety capsule |

| No.of mould bores | 9 | 21 |

| Power | 380/220V,50/60Hz,7kW | 380/220V,50/60Hz,11kW |

| Noise | <70dB | <70dB |

| Machine dimensions | 980x980x2100mm | 1610x1210x2180mm |

| Net weight | 1000kg | 2200kg |

| C Type Automatic Capsule Filling Machine | ||||

|---|---|---|---|---|

| Machine model | NJP-800C | NJP-1200C | NJP-2000C | NJP-3500C |

| Max capacity | 48000capsules/h | 72000capsules/h | 120000capsules/h | 210000capsules/h |

| Suit for capsule size | 00#-5# and safety capsule | 00#-5# and safety capsule | 00#-5# and safety capsule | 00#-5# and safety capsule |

| No.of mould bores | 6 | 9 | 18 | 26 |

| Power | 380V,50Hz,5.05kW | 380/220V,50/60Hz,6kW | 380/220V,50/60Hz,10kW | 380/220V,50/60Hz,12kW |

| Noise | <75dB | <75dB | <75dB | <75dB |

| Machine dimensions | 1080x1240x1930mm | 1180x1340x1980mm | 1500x1350x2100mm | 1386x1156x2100mm |

| Net weight | 800 kg | 1000kg | 1600kg | 2500kg |

Comprehensive Solutions

Explore HiF Machine’s extensive lineup of pharmaceutical machinery and packaging solutions, tailored for maximum efficiency and value.