Metal Detector

Metal Detector

HiF Machine’s Metal Detectors ensure product safety by rapidly and reliably identifying metal contaminants in materials. Designed for high-volume applications, these detectors prevent costly product recalls and maintain consumer confidence. We offer a range of models to suit various product types and throughput requirements.

Metal Detector T68

The pharmaceutical Metal Detector which adopts German technology with high precision, sensitivity and stability is designed to detect tablets, capsules and granules. It is suitable for detecting and removing magnetic and non-magnetic metal foreign bodies in tablets and capsules. Small metal chips and wires embedded in the product can also be removed quickly online (electric).

Digital Metal Separator SAYP-700S

Metal Separator SAYP-700S is widely used in pharmaceutical industry, health product industry, food industry, chemical industry and other fields. It is applicable to detecting and separating metal impurities in tablets, capsules, candies and other products during production or processing.

Pharmaceutical metal detector free fall metal separator CSJ-W150/200

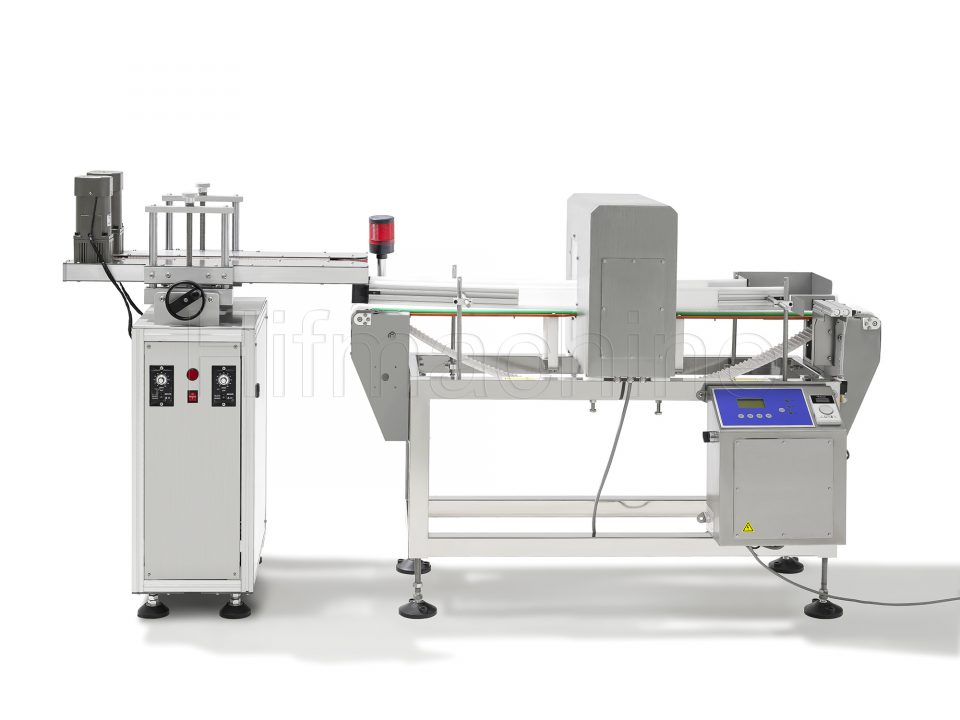

Metal detection machines are primarily used for detecting bulk and packaged products, applicable to industries such as food, pharmaceuticals, plastics, chemicals, wood, textiles, and others. The equipment can detect all magnetic and non-magnetic metal impurities (such as iron, stainless steel, aluminum, etc.), even if metal impurities are wrapped in product particles, it can accurately detect and eliminate them through the rejection unit.

Pharmaceutical metal detector free fall metal separator SAYP-600

The free-fall metal separator uses the principle of electromagnetic induction to inspect the inspected items passing through the pipeline. When a metal signal above the set value is detected, a sound and light alarm occurs and the unqualified products are automatically eliminated through a flap during the falling process.

Pharmaceutical metal detector free fall metal separator CSJ-990

The free-fall metal separator uses the principle of electromagnetic induction to inspect the inspected items passing through the pipeline. When a metal signal above the set value is detected, a sound and light alarm occurs and the unqualified products are automatically eliminated through a flap during the falling process.